|

"ARC" REFLECTIVE OPTICAL COATINGS

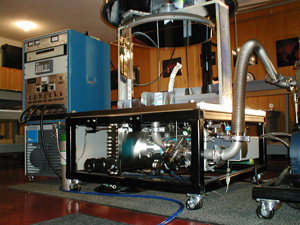

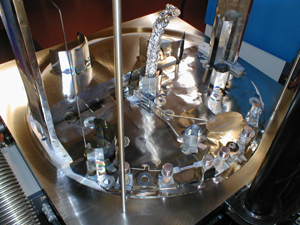

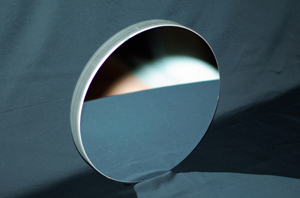

Our cyropumped optical thin film PVD system was specifically designed for coating telescope mirrors. The "ARC" coating process produces reflective coatings that are brilliant in their appearance, free of coloration and have uniform thickness from the center to edge. The coatings are exceptionally durable and well suited for use in the environments associated with observing. Galaxy Optics has fabricated and coated thousands of mirrors. When you choose us for your optical coating needs you can be sure you are getting the absolute best.

Our cyropumped optical thin film PVD system was specifically designed for coating telescope mirrors. The "ARC" coating process produces reflective coatings that are brilliant in their appearance, free of coloration and have uniform thickness from the center to edge. The coatings are exceptionally durable and well suited for use in the environments associated with observing. Galaxy Optics has fabricated and coated thousands of mirrors. When you choose us for your optical coating needs you can be sure you are getting the absolute best.

How the "ARC" Coating Process Works:

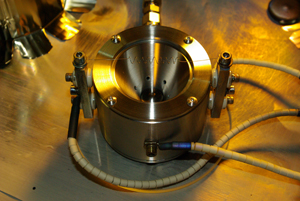

"ARC" is a trademark of Galaxy Optics and is an acronym for "Activated Reactive Coating". The "ARC" optical coating process operates on the exact same principals as "IAD" or "Ion Assisted Deposition". Activated Reactive Coating is the process of ionizing pure oxygen or other reactive or inert gases at very low pressure into high-energy plasma. The aluminum overcoating process for telescope mirrors requires the use of refractory metal oxide compounds as starting materials. The two most common overcoat compounds for the aluminum layer are silicon monoxide and titanium monoxide. The metal monoxides must be fully oxidized during the coating process to form silicon dioxide the low refractive index material and titanium dioxide the high refractive index material. "ARC" has two very important qualities, the high-energy ionized oxygen plasma drives the oxidation reaction to completion assuring a completely transparent film with a low extinction coefficient and the increased molecular energy is sufficient to force the SiO2 or TiO2 molecules to form densely packed coating layers that are extremely hard. This is the same optical coating technology used in the manufacture of optics for use in high-energy laser systems.

"ARC" is a trademark of Galaxy Optics and is an acronym for "Activated Reactive Coating". The "ARC" optical coating process operates on the exact same principals as "IAD" or "Ion Assisted Deposition". Activated Reactive Coating is the process of ionizing pure oxygen or other reactive or inert gases at very low pressure into high-energy plasma. The aluminum overcoating process for telescope mirrors requires the use of refractory metal oxide compounds as starting materials. The two most common overcoat compounds for the aluminum layer are silicon monoxide and titanium monoxide. The metal monoxides must be fully oxidized during the coating process to form silicon dioxide the low refractive index material and titanium dioxide the high refractive index material. "ARC" has two very important qualities, the high-energy ionized oxygen plasma drives the oxidation reaction to completion assuring a completely transparent film with a low extinction coefficient and the increased molecular energy is sufficient to force the SiO2 or TiO2 molecules to form densely packed coating layers that are extremely hard. This is the same optical coating technology used in the manufacture of optics for use in high-energy laser systems.

Standard Galaxy Optics Coatings:

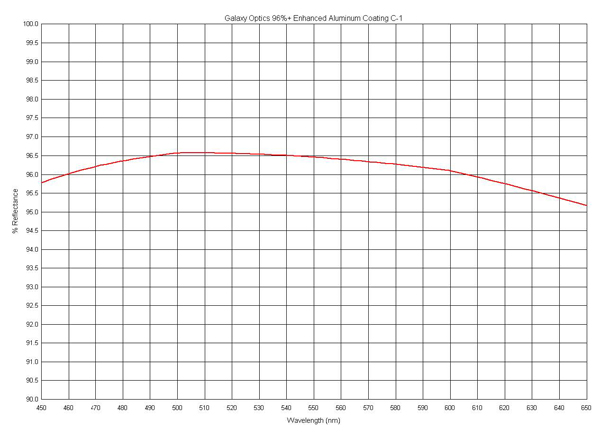

ENHANCED ALUMIUM COATINGS

C-1 95% Average Visual Reflectivity @ 0 Degrees AOI

C-3 95% Average Visual Reflectivity @ 45 Degrees AOI

QUARTZ PROTECTED ALUMINUM COATINGS

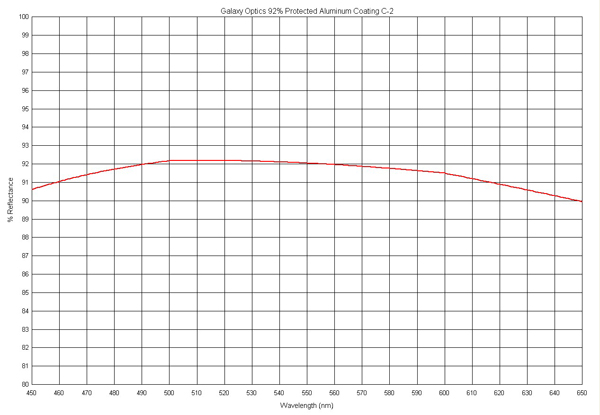

C-2 90% Average Visual Reflectivity @ 0 Degrees AOI

C-4 90% Average Visual Reflectivity @ 45 Degrees AOI

Custom Optical Coatings:

We can produce thin film optical coatings to meet your wavelength specifications from UV to IR. Please contact us for a quote.

Pricing:

C-1 and C-2 Primary Mirror Coatings

|

Diameter *

|

C-1

|

C-2

|

|

14.5"

|

$ 600

|

$ 575

|

|

16.0"

|

$ 650

|

$ 625

|

|

18.0"

|

$ 800

|

$ 775

|

|

20.0"

|

$ 1100

|

$ 1075

|

|

22.0" **

|

$ 1400

|

$ 1375

|

|

24.0" **

|

$ 1800

|

$ 1775

|

|

|

|

* Non-standard mirror diameters add $50.00 for mounting fixture tooling. ** Maximum Edge Thickness: 1.6"

|

C-3 and C-4 : 45 Degree AOI Elliptical Diagonal Mirror Coatings

|

|

M.A. Diameter

|

C-3 @ 45 AOI

|

C-4 @ 45 AOI

|

|

2.60"

|

$ 150

|

$ 125

|

|

3.10"

|

$ 150

|

$ 125

|

|

3.50"

|

$ 200

|

$ 175

|

|

4.00"

|

$ 250

|

$ 225

|

|

4.50"

|

$ 300

|

$ 275

|

|

5.00"

|

$ 350

|

$ 325

|

|

5.50"

|

$ 375

|

$ 350

|

|

6.00"

|

$ 425

|

$ 400

|

|

6.50"

|

$ 450

|

$ 425

|

|

|

Notice: Prices Effective August 30, 2024 and are subject to change without notice.

|

Primary Mirror Coating Removal and Cleaning Service: $100

Diagonal Mirror Coating Removal and Cleaning Service: $50

Galaxy Optics uses a dilute solution of hydrochloric acid and copper sulfate to remove your old coating. This solution safely removes the old coating without affecting the underlying glass or optical figure.

Additional discounts for bulk optical coating orders are available.

Please contact Galaxy Optics for a quote and delivery schedule.

CUSTOMER SATISFACTION GUARANTEE

Optical coatings are guaranteed for one year. Galaxy Optics does not warranty against coating damage caused by moisture, acid dew, acid rain, chemical exposure, neglect, animal or insect excrement, improper cleaning methods, or improper storage.

GUARANTEED OPTICAL COATING REFLECTIVITY SPECIFICATIONS

C-1 and C-3 - Greater than 95% Average Reflectivity 450nM > 650nM

C-2 and C-4 - Greater than 90% Average Reflectivity 450nM > 650nM

|